No problem. Pretty much of my understanding, the CDI route will work, just have to be a little more on the safe side with the timing, and and ECU you can push things further to eek out a little more performance. Back around the 70's Oldsmobile made an experimental 455 v8 that they twin turbo'ed and tested EFI as well as Carb'ed. If I recall correctly, both ended up roughly 700hp. I guess the performance for EFI wasn't good enough so GM didn't use EFI for quite a long time. I think around the mid 80's is when they started making it main stream. My dad was a big Oldsmobile fan, he used the 350/455 engines in trucks because they were known as the king of torque back then.

Anyway, this should be a pretty interesting project to follow. Small engine turbos aren't super mainstream except in the side by side world of what I'm aware of atleast. Would be pretty interesting to turbo an ATC350X, but at the same time it would probably be better for drag racing and such with that type of setup, not so sure if a trail rider machine would benefit much vs a high compression build.

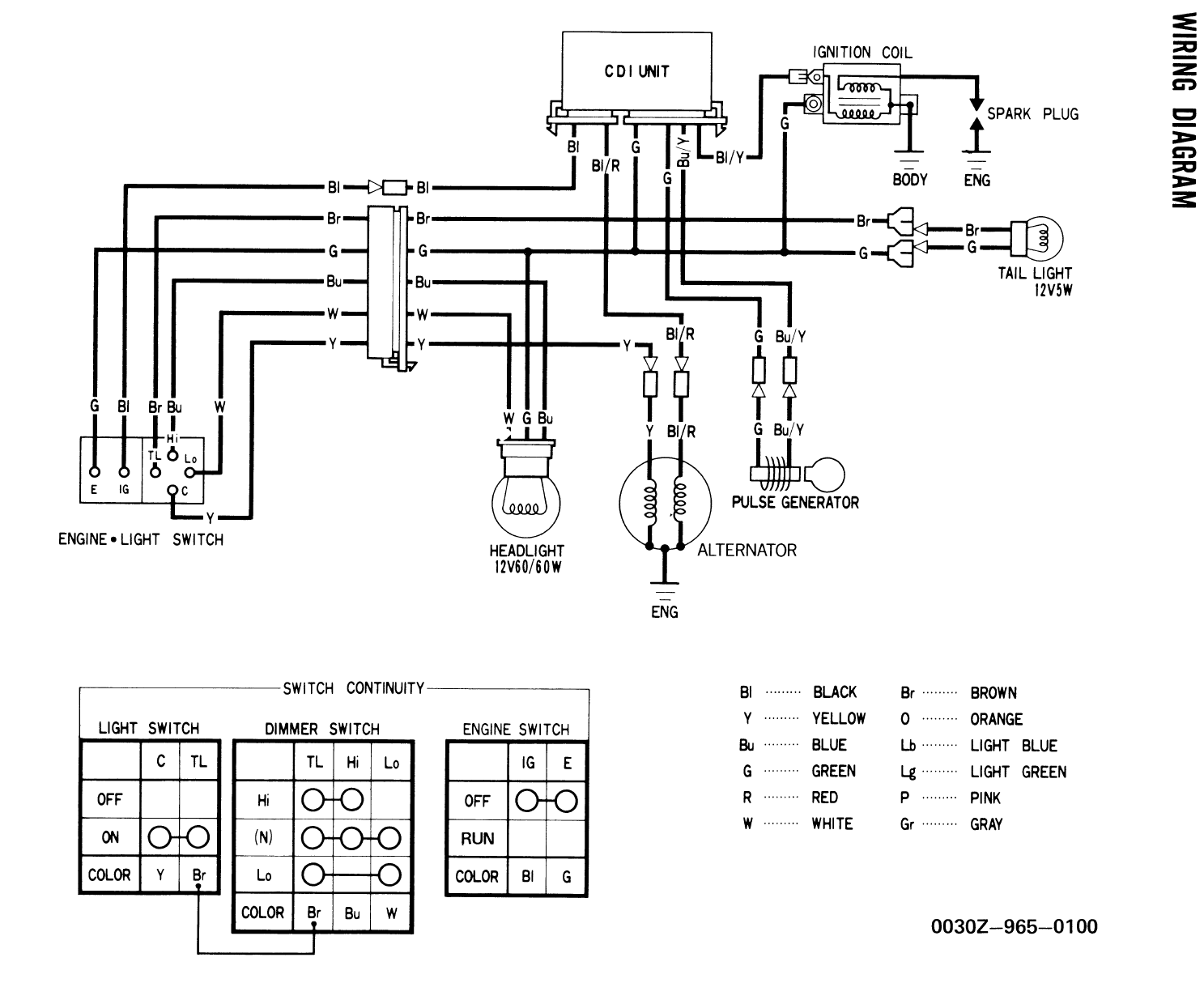

I guess another thing you could really use is a wire diagram to visualize how things interconnect. This diagram is from the 83-85 Honda

service manual. For the left handle bar controls, the only two wires you'd have to worry about is the kill and ground (E/IG, or G and Bl wires). Ignore the light wires (blue, white, brown, and the green sections not used which is ground). Yellow wire is the AC power source directly from the engine, that plus a wire to ground would be needed for a voltage regulator/rectifier's AC input.

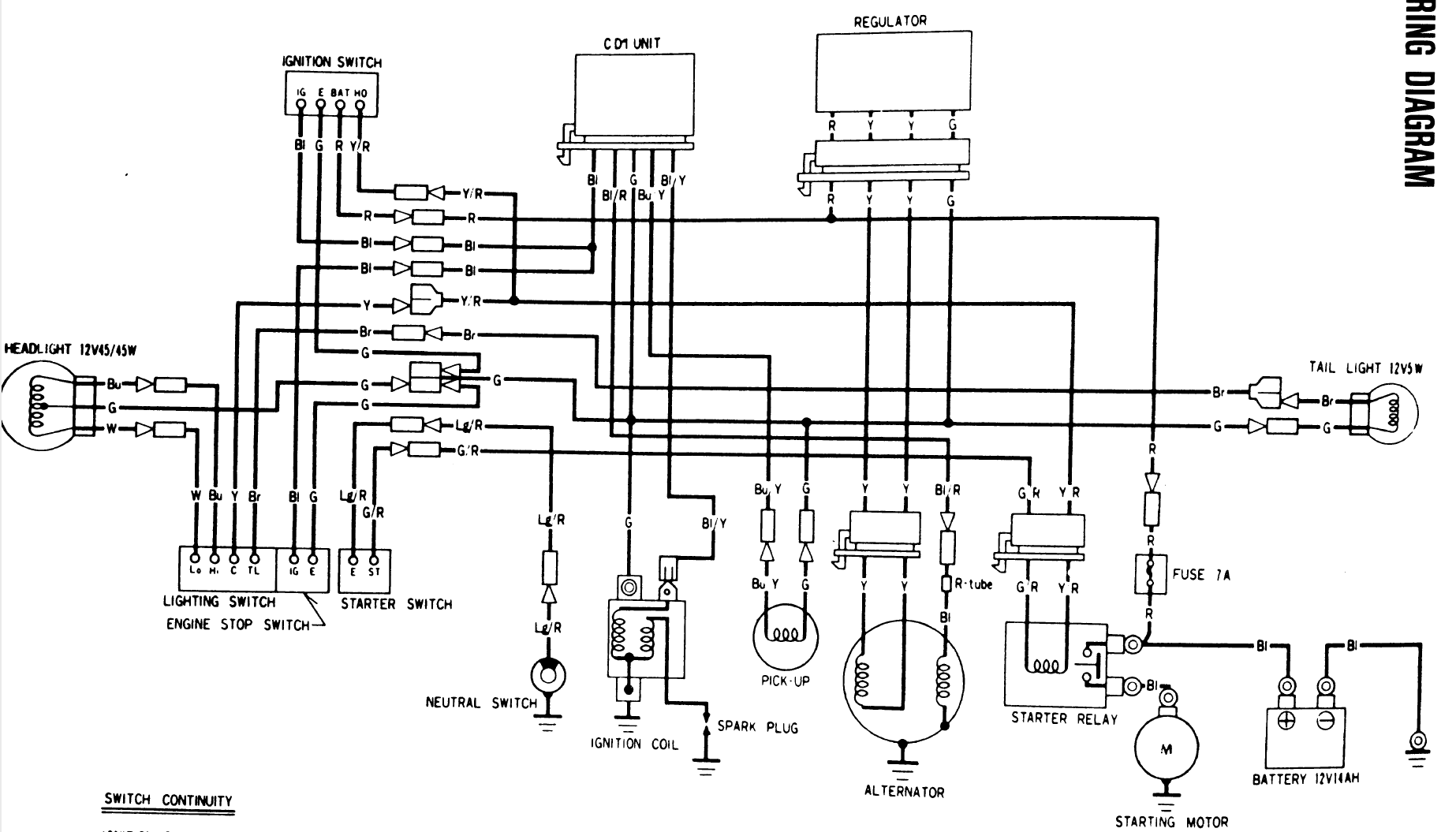

Here's a wire diagram for the 82-83 ATC200E (simplest machine I can think of with a battery factory). Pretty much everything is the same + the battery and electric start wiring. Main focus points for your project is how the alternator is wired to the regulator. The stator doesn't ground on that machine so it actually has 2 dedicated wires. Red wire would be the charging/rectified DC+ out and the green is the neg (don't ground on your machine). A fuse is suggested near the battery so if any wire shorts out, the fuse blows instead of having an electrical fire. Besides that, it's as simple as wiring up the fuel pump to the battery with a switch inline to turn it on/off. Most atv ignition switches from that era are 4 wire, off shorts the ignition wires out, and on shorts the power supply wires, so that kind of switch would work for your machine to control ignition + fuel pump at one time. If you do end up using the stock CDI for the 200x, let me know which year and I can get a pin out, there were 3 CDI's possible, 83 rectangle 6 pin, 84-85 round 6 pin, and 86-87 4+2 pin.

Here's a quick reference guide for wire colors on the 200x

Green - Frame ground

Yellow - Power source (AC)

Black/red - CDI power source (exciter coil, high voltage AC)

Blue/yellow - pulse generator signal wire

Black/yellow - ignition coil signal wire

Black - kill wire (short to ground to kill ignition)

Lighting wires

Brown - Tail light

Blue - brights

White - dims

Reply With Quote

Reply With Quote