This is just one of a many I hope to come of this type of thread. I wanted to do a write up on how I rebuild my calipers. So many guys seem to struggle when it comes to rebuilding calipers. This is how I do it.

PART I :

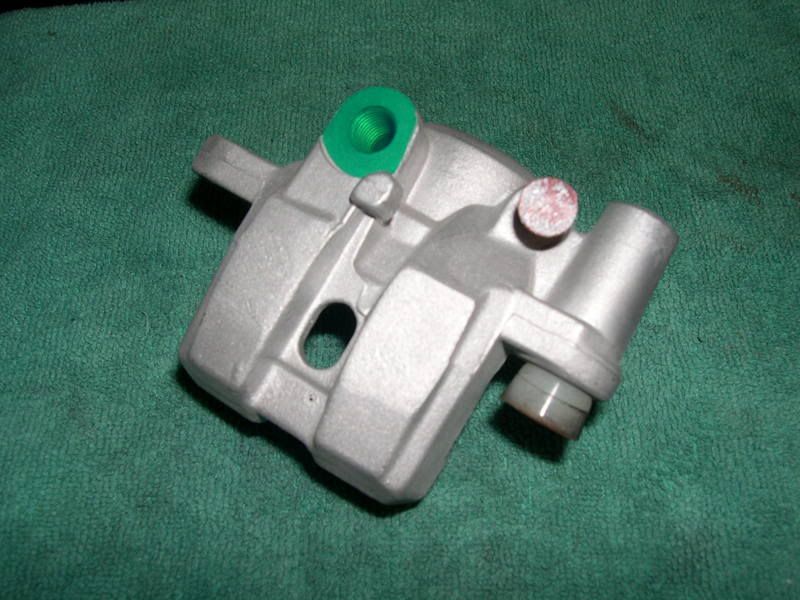

Like most calipers on our trikes they are old,beaten,battered and almost always never working when you pick up a trike. Pistons are seized. Bleeders are snapped off. Etc. Most of them look like this

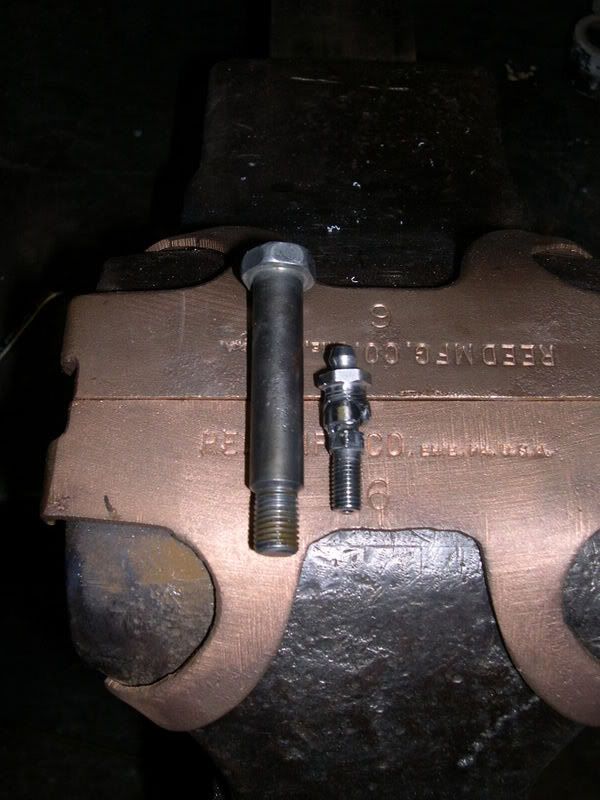

When I recieved this caliper it was indeed in sad shape. Luckly the bleeder was not froze in the caliper and it came out without a fight. However the piston was frozen solid!!! So what I do is force them out with grease. Thus utilizing the force of hydraulic pressure. This can be done with your old grease gun in the garage. I simply take the old bleeder and cut the head off of it and weld a grease zerk on the end. Then I just use an old bolt to block of the hole where the brake line gets bolted to the caliper.

Brake fitting and spare bolt

Mounted up in the vise ready for the removal of the piston.

To be continued.......

Reply With Quote

Reply With Quote

. This is the best way IMO.

. This is the best way IMO.